|

We can help you find the most suitalbre machines for your needs.

Using the newest technology and patent,Dewate high pressure air compressor units withstand severe tests and feature higher efficiency and reliability(ability to work 24 hours per day),longer service life,lower noise,vibration,exhaust temperature and oil consumption.

Applications

Dewate high pressure air compressors are designed for the fields of hydropower,PET bottle blowing,leak check,military affairs,etc.Their major performance indicators reach or exceed advanced level of the compressors of the same kind.

Main Features of Dewate Air Compressor Especially for PET Bottle Blowing

|

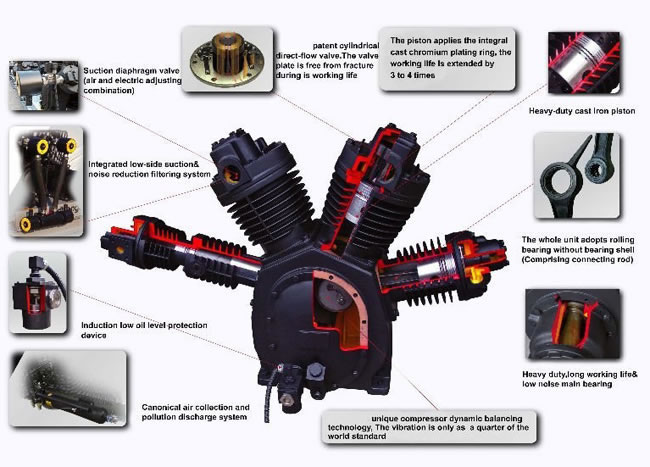

1.The high pressure air compressor uses a high quality cylindrical direct-flow valve.The valve is made from the stainless steel belt imported from Sweden and is free from fracture during the working life.

2.It has a suction diaphragm valve(air and electric adjusting combination).

3.Monomer cast chromium plated rings are applied and the working life is extended by 3 to 4 times.It has a heavy-duty cast iron piston.

4.It offers an induction low oil level protection device.

5.The whole unit(comprising connecting rod)uses rolling bearing without bearing shell.

6.The high pressure air compressor is heavy duty.has a long working life,and low noise main bearing.

7.It offers integrated low-side suction and a noise reduction filtering system.

8.It has canonical air collection and a pollution discharge system.

9.Unique dynamic balancing technology is used in the high pressure air compressor and largely reduces the vibration of the air compressor.

| High Pressure Air Compressor(PET Bottle Blowing) |

| Series |

Model |

FAD |

Pressure |

Power |

Weight |

Dimension |

| (M³/min) |

(CFM) |

(bar) |

(PSL) |

(KW) |

(kg) |

L*W*H(mm) |

| 09WM |

1130 |

09wm-1130 |

1 |

36 |

30 |

435 |

11 |

670 |

1520×800×950 |

| 09wm-1130-YQ |

1 |

36 |

30 |

435 |

11 |

546 |

1880×850×1050 |

| 2-09wm-1130 |

2 |

71 |

30 |

435 |

22 |

1050 |

1900×1700×950 |

| 1130h |

09wm-1130h |

1.2 |

43 |

30 |

435 |

11 |

670 |

1520×800×950 |

| 09wm-1130-YQ |

1.2 |

43 |

30 |

435 |

11 |

546 |

1880×850×1050 |

| 2-09wm-1130H |

2.4 |

85 |

30 |

435 |

22 |

1090 |

1900×1700×950 |

| 1530 |

09wm-1530 |

1.2 |

43 |

30 |

435 |

15 |

680 |

1520×800×950 |

| 09wm-1530-YQ |

1.2 |

43 |

30 |

435 |

15 |

580 |

1880×850×1050 |

| 2-09wm-1530 |

2.4 |

85 |

30 |

435 |

30 |

1150 |

1900×1700×950 |

| 34SH |

1530 |

34SH-1530 |

1.3 |

46 |

30 |

435 |

15 |

650 |

1650×1000×1000 |

| 2-34SH-1530 |

2.6 |

92 |

30 |

435 |

15×2 |

1500 |

2150×2000×1000 |

| 1530T |

34SH-1530T |

1.3 |

46 |

30 |

435 |

15 |

550 |

1150×900×1420 |

| 2-34SH-1530T |

2.6 |

92 |

30 |

435 |

15×2 |

1120 |

2350×1100×1650 |

| 3-34SH-1530T |

3.9 |

138 |

30 |

435 |

15×3 |

1700 |

3800×1000×1750 |

| 4-34SH-1530T |

5.2 |

184 |

30 |

435 |

15×4 |

2270 |

4650×1200×1650 |

| 1830 |

34SH-1830 |

1.6 |

57 |

30 |

435 |

18.5 |

660 |

1650×1000×1000 |

| 2-34SH-1830 |

3.2 |

113 |

30 |

435 |

18.5×2 |

1510 |

2150×2000×1000 |

| 1830T |

34SH-1830T |

1.6 |

57 |

30 |

435 |

18.5 |

550 |

1150×900×1420 |

| 2-34SH-1830T |

3.2 |

113 |

30 |

435 |

18.5×2 |

1150 |

2350×1100×1650 |

| 3-34SH-1830T |

4.8 |

170 |

30 |

435 |

18.5×3 |

1750 |

3800×1000×1750 |

| 4-34SH-1830T |

6.4 |

226 |

30 |

435 |

18.5×4 |

2300 |

4650×1200×1650 |

| 83sw oil free |

2230 |

83SW-2230 |

1.9 |

67 |

30 |

435 |

22 |

730 |

2190×1020×1050 |

| 2-83SW-2230 |

3.8 |

135 |

30 |

435 |

22×2 |

1600 |

3800×1100×1260 |

| 3-83SW-2230 |

5.7 |

202 |

30 |

435 |

22×4 |

2570 |

5720×1100×1270 |

| 2240 |

83SW-2240 |

1.9 |

37 |

30 |

435 |

22 |

730 |

2190×1020×1050 |

| 2-83SW-2240 |

3.8 |

135 |

30 |

435 |

22×2 |

1600 |

3800×1100×1260 |

| 3-83SW-2240 |

5.7 |

202 |

30 |

435 |

22×3 |

2570 |

5720×1100×1270 |

Detailed description:

1.Low exhaust temperature (when exhaust pressure is 7.0 Mpa, exhaust temperature is equal to or less than 170; aftercooler-processed temperature at outlet is only 15 to 20 higher than ambient temperature) and oil consumption is low (oil consumption is less than 2.6g/h).

2.Advanced direct-flow valve technology is used for low pressure air compressor, which increases air output by 13% and reduces energy consumption by 11%,

3.Ring valve made from Sweden stainless steel strip is used for high pressure air compressor.

4.In order to ensure safety and reliability of air compressor, redundancy design principle is applied and multiple protection measures are taken; overload protection; overheat protection; phase-failure protection; undervoltage protection; drain and exhaust when unloading and stopping running the equipment; ensure zero-pressure start; ensure interstage timed drainage when air compressor operates continuously, which effectively prevents water flood and liquid impact.

5.There are interstage safety valve and pressure indicator; pressure and temperature measuring interface is available; it is convenient for user to install and debug remote monitoring system.

6.Use high quality multi-stage complex impedance suction filter featuring low noise and pollution resistance.

7.Advanced inductive low oil level alarm (or forced stoppage) device featuring stable performance and reliability and ensuring that the compressor is free from oil shortage and burn-in failure. |